1-3 Random Fibre Composites

1-3 Random Fiber Composites

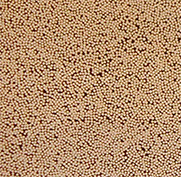

Smart Material manufactures 1-3 composites using piezo ceramic fibres as active rods, randomly distributed over the composite active area. 1-3 fiber composites are prepared by epoxy infiltration of fiber bundles and bundles and dicing of the cube-shaped blocks perpendicular to the direction of the fibers. This patented method is also called Arrange & Fill. A random distribution of the fibers allows for excellent suppression of lateral frequency modes.

1-3 Random Fiber A&F Composite specifications:

- Frequencies 80kHz to 8MHz

- PZT Navy type II

- Fill Factors 35%,65%,80%

- Maximun dimensions 8cm by 8cm, larger and curved on request

- Various epoxy and polyurethane interstitial materials available.

- Operational temperatures up to 135℃

- Available with Gold, Copper-Tin electrodes

1-3 Random Fiber A & F Composites specifications

Smart Material manufactures 1-3 composites using piezo ceramic fibers as active rods. PZT fiber composites are a cost-effective alternative compared to the Dice & Fill method. 1-3 fiber piezo composites are prepared by epoxy infiltration of fiber bundles and dicing of the cube-shaped blocks perpendicular to the direction of the fibers. This patented method is also called Arrange & Fill.

Using piezo ceramic fibers with 105µm, 250µm and 800µm diameters will yield fill factors of approx. 35%, 65% and 80% in a random distributed cross-section.

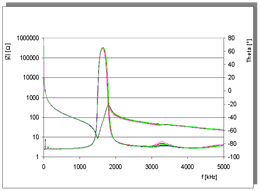

The random fiber composite material shows superior properties for ultrasound transduction, which is due to reduced acoustic impedance and high coupling factor. Additionally, 1-3 fiber composites with random element distribution yield an increased spurious mode suppression due to the random spacing.

1-3 Random Fiber Composite product specifications and selections

| Resonance Frequencies | 80kHZ up to 8MHz |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fill Factor | 35%, 65%, 80% |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PZT Materials | PZT Navy Type II |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Acoustic Impedance | 12 MRayl to 27 MRayl |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Available Electrodes | CuSn (Copper with Tin flash layer) Au (Gold) |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimensions | Max. 100mm by 100mm, various round diameters |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Coupling Coefficient kt | 0.61 to 0.68, fiber diameter - max. frequency aspect ratio rules apply |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operational Temperatures | Typical 95°C, 135°C on request | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Interstitial Materials | Various Epoxy systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Ultrasound Applications for 1-3 Random Fiber Composites

- NDT,Non-Destructive Testing

- SONAR, single element transducer

- Air Ultrasound Transducer

- Flow Control and Measurement

Due to the Arrange & Fill production method the raw 1-3 fiber composite material are typically blocks of up to 10cm length and the lateral dimensions of the targeted element.

The A&F method also allows to machine 1-3 composites into various shapes and forms, in addition to slicing elements with the desired resonance frequency of the raw fiber block.

Plano-Concave This includes precise concave or convex contours for superior broadband ultrasound receiver applications.

The Arrange & Fill

production method is easily scalable for volume quantities which also allows for short lead time, a major advantage over the commonly used Dice & Fill method.

Smart Material offers various standard Epoxy and Polyurethane systems as the interstitial material for its random fiber composites, often called filler. The different, available filler materials allow for operational temperatures between 95°C and 135°C.